Shapeoko XXL - This is the Shapeoko XXL, nearly FOUR times the cutting area of the Shapeoko v3. The folks at Shapeoko recommend the DeWalt D26200 or Makita RT0700C to use with the machine. This version of the Shapeoko XL does NOT include a trim router, this will need to be purchased separately.

It uses a 1.25hp spindle and NEMA 23 stepper motors for motion control with an accuracy of about 0.005". Each Shapeoko XL has a cutting area of 838mm x 425 mm x 75mm (33" x 16" x 3") and an overall footprint of 1137mm x 607mm (44.8" x 24").

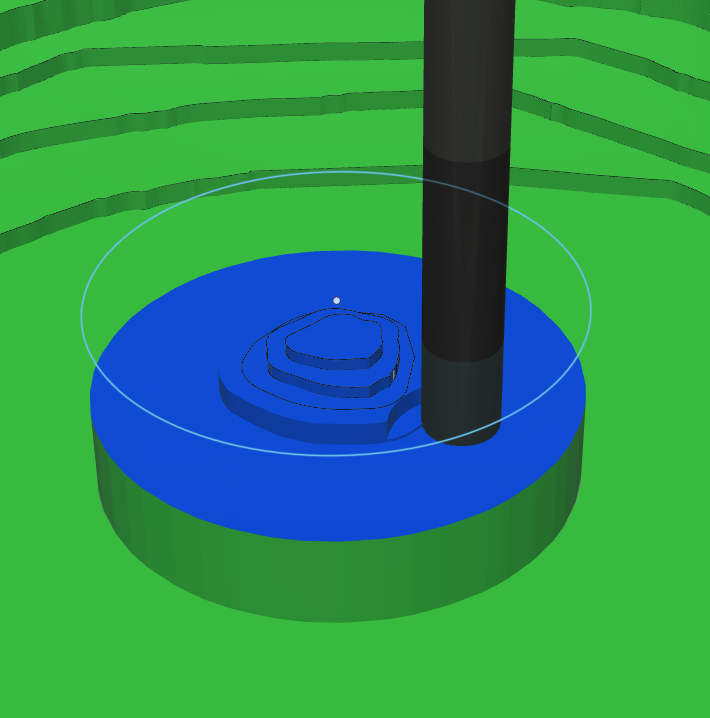

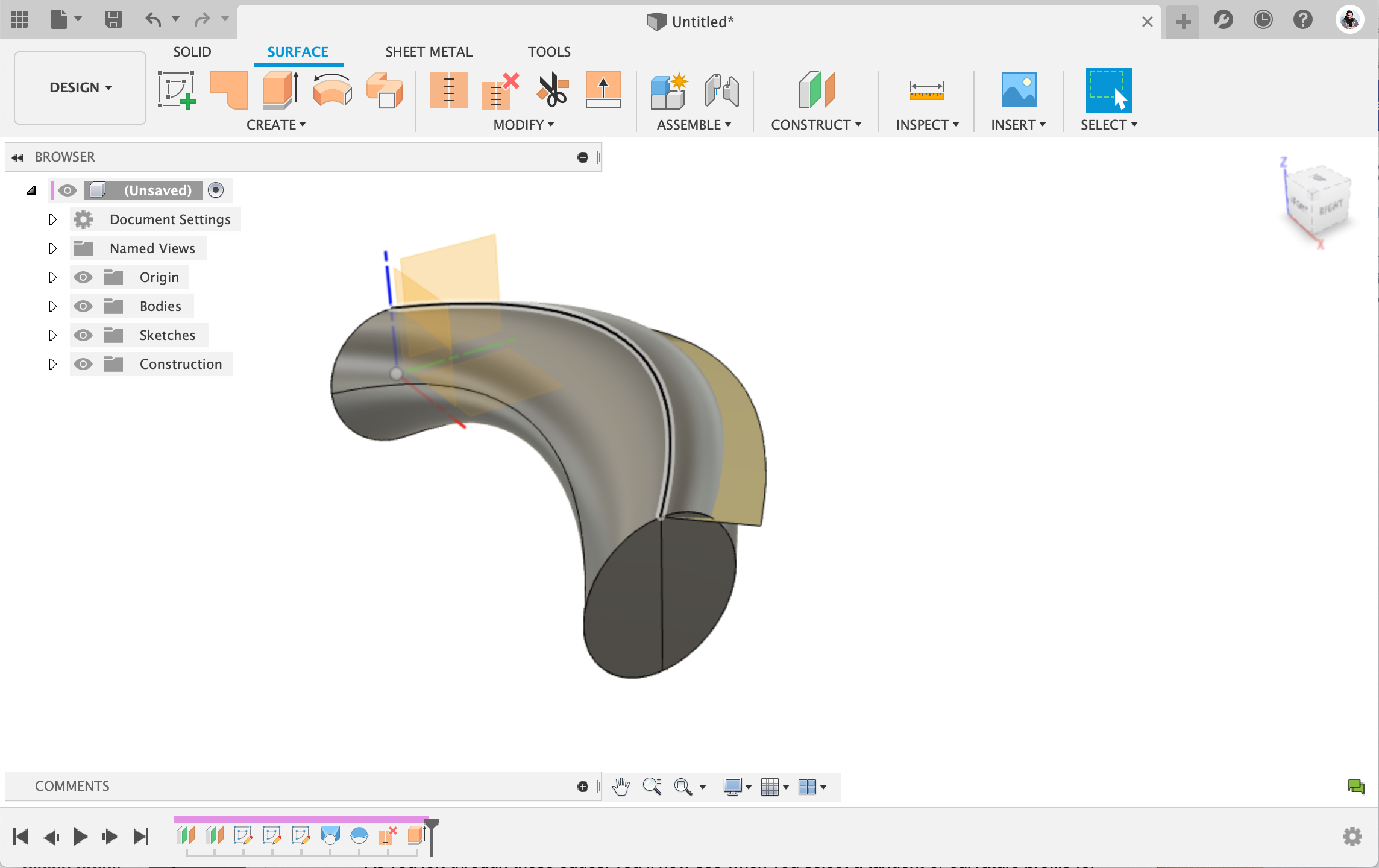

Shapeoko XL - The Shapeoko XL nearly doubles the cutting area of the Shapeoko v3. This board now includes thermal gap filler to help with ESD issues. Just make sure your motors are the correct size and start playing. The board can accept G-code commands from your computer and control your motors. Do you have your own gantry with its own steppers and just need a controller? If so this board is for you. It has 3 stepper motor drivers as well as an Arduino compatible processor running the GRBL software. Stepoko Board - This is the bare Stepoko board. Based on a custom aluminum extrusion that serves as both the frame and the motion system, it comes with NEMA 23 stepper motors for motion control, GT2 Belting, and a Carbide Motion Controller to run both G-Code and GRBL. Shapeoko v3 - With the exception of the trim router, this framework has just about everything you need to get started with your own desktop CNC machine. If this paragraph is incomprehensible to you check out the definitions below. Check out our various Stepoko and Shapeoko products along with various support parts. Together you are on your way to a complete CNC Machine. The Shapeoko on the other hand is a complete 3-axis gantry. The Stepoko runs Grbl software and is able to connect to your computer, accept G-code and translate that to stepper motor commands (complete with stepper motor drivers). Hi mates how are you guys today, after drawing what it seems to be 4th and 5th axis for my Shapeoko, i started the journey of understanding how to set up the machine in fusion 360 and where WCS needs to be located, also learned how to enable 5 axis post for my MASSO controller, scary stuff the first time you see all of it but i think i may be on the money.The Stepoko and Shapeoko are designed to help you build your own CNC router or other 3-axis system.

0 kommentar(er)

0 kommentar(er)